webforbiz

Type of Backflow

There are different type of Backflow Devices.

These devices are:

Hose Connection Vacuum Breaker HCVB

The Dura Vacuum Breaker is a low hazard backflow device, it is a single check valve spring loaded to a closed position with atmospheric vacuum breaker vent. They are generally attached to a hose tap to prevent backsyphonage for example in the event of cross connection when filling a swimming pool. It can also be used in other applications including: laboratory sinks, service sinks, soap dispensers etc.

Level of Hazard : Low Hazard Device (Back pressure & Backsyphonage)

Dual Check Valve DUCV

The Dual Check Backflow Preventer was designed to be installed down stream from the house water meter to reduce the potential backflow of pollutants from the house or yard into water mains. Each of the two spring loaded check valves remains tightly closed at zero flow. At rated flow, both checks are fully open. If the back pressure increases above the supply pressure, there is a reverse direction of flow, the check valves close and backflow is prevented. Approved to AS2845-1.

Level of Hazard : Low Hazard Device (Back pressure & Backsyphonage)

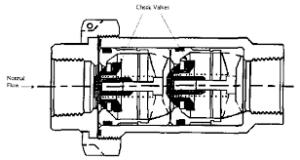

Double Check Valve.

Double Check Valves 15mm through 50mm shall consist of two independently acting in-line check cartridges, two resilient seated ball type isolating valves (to be installed immediately upstream of the line strainer and immediately downstream of the device) and three resilient seated test cocks. A line strainer (supplied) shall be installed immediately upstream of the device, except where used in fire service installations. The device body shall be removable from the line via M&F barrel unions (supplied) and to be installed immediately either side of the device body. Further details refer installation instructions in pack.

Level of Hazard : Medium Hazard Device (Back pressure & Backsyphonage)

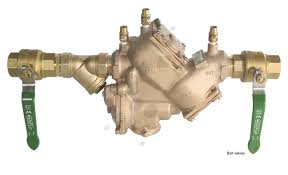

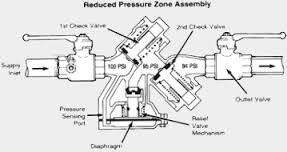

Reduced Pressure Zone Device RPZD

Reduced Pressure Zone Devices 15mm through to 50mm shall consist of an automatically opening differential pressure relief valve located so that its valve seat and port to atmosphere are below the lowest point of the first check valve (to preclude backsyphonage) and between two resilient seated ball type isolating valves (to be installed immediately upstream of the line strainer and immediately downstream of the device) and three resilient seated test cocks. A line strainer (supplied) shall be installed immediately upstream of the device, except where used in fire service installations. The device body shall be removable from the line via M&F barrel unions (supplied) and to be installed immediately either side of the device body. Further details refer installation instructions in pack.

Level of Hazard : High Hazard Device (Back pressure & Backsyphonage)

BackFlow Testing Service Melbourne

This gallery contains 8 photos.

Need to get your Back flow testing carried out?

Think Smart Plumning are licensed plumbers that are able to test and install backflow preventers to ensure that any contamination from your supply is not flowing into the local water supply system.

A backflow prevention containment device ensures that the drinking water supplied to Melbourne properties cannot be contaminated by any cross connections from your property.

Examples of potential source of contamination:

- Fire hose reels (FHR)

- Irrigation

- Swimming pools

- Vehicle-maintenance pits

- Ornamental ponds

- Air-conditioning towers

- Vehicle/bin-washing bays

- Chemical injection areas

All properties connected to the Melbourne water supply will need to have a backflow prevention device installed appropriate to the property’s hazard rating set out by the legislation.

Backflow testing needs to be regularly carried out to ensure that your property isn’t at risk of contaminating the mains water supply. A faulty backflow preventer can not only cause serious damage to your water supply but can result in leaks and also poor water pressure to your building.

Examples of properties requiring backflow prevention:

- Motels and unit complexes

- Hotels

- Vehicle-repair workshops

- Shops

- Restaurants

- Caravan parks

- Medical and dental surgeries

- Car and plant-washing facilities

- Dry-cleaners and laundries

- Hospitals and funeral parlours

- Club houses for sports

- Schools

- Day care centres and kindergartens

- Pest control and water-carrying vehicles

- Botanic gardens

- Petrol Stations

Think Smart Plumbing are licensed and certified to carry out backflow testing and has years of experience in backflow prevention. Think Smart Plumbing offers a complete backflow prevention service including installation, audits, backflow testing servicing and backflow repairs. So if you need to have your backflow device checked give our team of master plumbers a call.

Annual Backflow Testing

A Backflow valve has to be tested yearly. After testing all forms must be sent to the local council. If valves are not tested the water Authority have the power to take action against the owner.