Type of Backflow

There are different type of Backflow Devices.

These devices are:

Hose Connection Vacuum Breaker HCVB

The Dura Vacuum Breaker is a low hazard backflow device, it is a single check valve spring loaded to a closed position with atmospheric vacuum breaker vent. They are generally attached to a hose tap to prevent backsyphonage for example in the event of cross connection when filling a swimming pool. It can also be used in other applications including: laboratory sinks, service sinks, soap dispensers etc.

Level of Hazard : Low Hazard Device (Back pressure & Backsyphonage)

Dual Check Valve DUCV

The Dual Check Backflow Preventer was designed to be installed down stream from the house water meter to reduce the potential backflow of pollutants from the house or yard into water mains. Each of the two spring loaded check valves remains tightly closed at zero flow. At rated flow, both checks are fully open. If the back pressure increases above the supply pressure, there is a reverse direction of flow, the check valves close and backflow is prevented. Approved to AS2845-1.

Level of Hazard : Low Hazard Device (Back pressure & Backsyphonage)

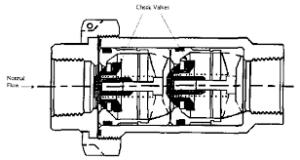

Double Check Valve.

Double Check Valves 15mm through 50mm shall consist of two independently acting in-line check cartridges, two resilient seated ball type isolating valves (to be installed immediately upstream of the line strainer and immediately downstream of the device) and three resilient seated test cocks. A line strainer (supplied) shall be installed immediately upstream of the device, except where used in fire service installations. The device body shall be removable from the line via M&F barrel unions (supplied) and to be installed immediately either side of the device body. Further details refer installation instructions in pack.

Level of Hazard : Medium Hazard Device (Back pressure & Backsyphonage)

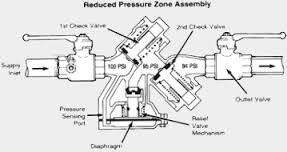

Reduced Pressure Zone Device RPZD

Reduced Pressure Zone Devices 15mm through to 50mm shall consist of an automatically opening differential pressure relief valve located so that its valve seat and port to atmosphere are below the lowest point of the first check valve (to preclude backsyphonage) and between two resilient seated ball type isolating valves (to be installed immediately upstream of the line strainer and immediately downstream of the device) and three resilient seated test cocks. A line strainer (supplied) shall be installed immediately upstream of the device, except where used in fire service installations. The device body shall be removable from the line via M&F barrel unions (supplied) and to be installed immediately either side of the device body. Further details refer installation instructions in pack.

Level of Hazard : High Hazard Device (Back pressure & Backsyphonage)